Elevate Efficiency: Necessary Tips for Preserving Undercarriage Parts Effectiveness

Elevate Efficiency: Necessary Tips for Preserving Undercarriage Parts Effectiveness

Blog Article

Take Full Advantage Of Efficiency With Sturdy Undercarriage Components

In the realm of heavy equipment and equipment, the duty of undercarriage parts is paramount in making sure ideal efficiency and long life. The effectiveness and performance of these elements can considerably influence the overall procedure of equipment, making the option of long lasting undercarriage components a vital decision for drivers and managers alike.

Benefits of Utilizing Durable Undercarriage Parts

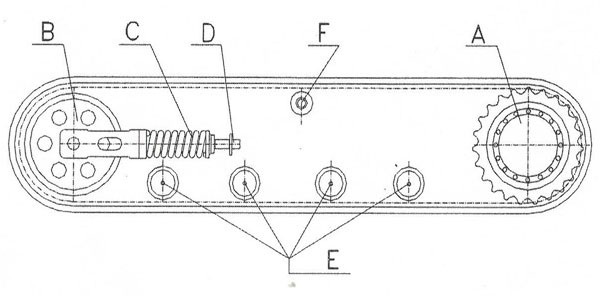

Utilizing resilient undercarriage components not only improves the long life of heavy equipment but also reduces maintenance prices considerably. By buying high-quality undercarriage elements, such as tracks, rollers, idlers, and gears, equipment drivers can experience increased uptime and improved overall performance.

Additionally, the longevity of hefty equipment is straight linked to the top quality of its undercarriage components. Durable parts can hold up against the roughness of demanding applications, making sure that the tools continues to be operational for prolonged periods. Therefore, drivers can avoid pricey downtime and maintenance costs, inevitably optimizing the roi for their machinery.

Variables Affecting Undercarriage Resilience

The toughness of undercarriage parts in hefty machinery is affected by numerous crucial variables that straight effect efficiency and long life. High-quality products, such as hard steel, are necessary for withstanding the extreme conditions and heavy loads that undercarriage components are subjected to - undercarriage parts.

Additionally, ecological elements can have a significant impact on the longevity of undercarriage components. Direct exposure to unpleasant materials, extreme temperatures, and severe working problems can speed up deterioration on undercarriage components. For that reason, choosing undercarriage parts that are specifically developed to hold up against these ecological challenges is essential for making certain resilience.

Furthermore, the style and engineering of undercarriage components have a straight influence on their resilience. Parts that are designed to disperse tons evenly, reduce friction, and lessen stress and anxiety concentrations are most likely to have a longer lifespan - undercarriage parts. By considering these important factors, tools drivers can optimize the resilience and performance of their undercarriage parts

Upkeep Tips for Lengthening Undercarriage Life

Carrying out normal upkeep regimens is crucial for expanding the lifespan of undercarriage parts in hefty equipment. To lengthen the undercarriage life, it is critical to often evaluate for deterioration. Routinely examine for loose or absent bolts, harmed rollers, or misaligned tracks, as these problems can rise and create further damages if not dealt with quickly. Additionally, make certain that the undercarriage is effectively lubed according to producer guidelines to decrease rubbing and stop early wear.

One more vital maintenance suggestion is to keep the undercarriage clean from dust, rocks, and debris. Build-up in the undercarriage can accelerate wear and rust, causing from this source costly repairs. Washing the undercarriage after operation in extreme conditions is advised to avoid these concerns.

Last but not least, monitoring and recording upkeep tasks can help in developing a positive upkeep timetable. Keeping in-depth documents of repair services, replacements, and assessments can offer important insights into the undercarriage's problem and efficiency over time, assisting in predicting and preventing prospective failures. By following these maintenance suggestions vigilantly, operators can substantially boost the durability and performance of undercarriage components in hefty machinery.

Picking the Right Undercarriage Components

Choosing proper undercarriage parts is crucial for taking full advantage of the effectiveness and longevity of heavy machinery. When it comes to picking the ideal undercarriage components, there are numerous aspects to consider.

Opting for trustworthy brands understood for generating high-performance and sturdy undercarriage components can significantly impact the total efficiency and longevity of the machinery. By carefully choosing the ideal undercarriage components, devices proprietors can improve efficiency, reduce downtime, and expand the life expectancy of their heavy machinery.

Instance Research Studies: Boosted Efficiency With Durable Parts

Incorporating sturdy undercarriage parts has shown considerable enhancements in equipment efficiency. One case research study entailed a building company that updated its excavator's undercarriage components to much more sturdy choices.

In an additional circumstances, a mining procedure changed the undercarriage parts of its excavator with high-grade, sturdy options. This button led to an impressive enhancement in the bulldozer's maneuverability and general performance. The equipment might navigate challenging surfaces extra efficiently, bring about enhanced operational effectiveness and lowered fuel usage.

Additionally, a logging company bought resilient undercarriage components for its forestry equipment. The updated elements showed prolonged life expectancy and increased resistance to abrasion from harsh terrain. The company experienced minimized maintenance prices and improved equipment uptime, ultimately improving its lower line. These situation studies emphasize the substantial advantages of making use of long lasting undercarriage parts in optimizing equipment performance and i was reading this durability.

Verdict

To conclude, using resilient undercarriage components can substantially enhance efficiency and long life of hefty machinery. Variables such as appropriate maintenance go now and choosing the appropriate parts play an important role in making best use of undercarriage longevity. By applying these techniques, companies can decrease downtime, rise effectiveness, and ultimately reduce operational prices. Study have shown that purchasing long lasting undercarriage components can result in improved overall efficiency and productivity in numerous industries.

The performance and efficiency of these components can considerably affect the overall procedure of machinery, making the selection of sturdy undercarriage parts a critical choice for supervisors and operators alike.Incorporating long lasting undercarriage parts has demonstrated substantial improvements in equipment performance. These instance research studies highlight the tangible advantages of utilizing resilient undercarriage parts in enhancing machinery performance and longevity.

In conclusion, making use of durable undercarriage components can dramatically enhance performance and long life of heavy machinery (undercarriage parts). Instance research studies have actually shown that spending in durable undercarriage parts can lead to improved total efficiency and performance in numerous markets

Report this page